This guide was designed to provide practical advice for developing and implementing a robust Food Safety Program based on the seven principles of HACCP.

A Food Safety Program is not only a legal requirement for most food businesses in Australia, it can also protect your business from the consequences of a serious food safety incident like a food-borne illness outbreak or a life-threatening allergic reaction to your food.

Introduction

The safety of food is essential for the success of any food business. For some businesses, food safety is often dismissed as an afterthought — or worse, a costly nuisance.

A Food Safety Program is not only a legal requirement for most food businesses in Australia, but it can also protect your business from:

- being the cause of a food-borne illness

- causing severe allergic reactions from food allergens

- losing customers due to a reputation of improperly handling food

A Food Safety Program is a set of written procedures that helps to prevent, reduce or eliminate food safety hazards. The program identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. This allows potential hazards to be corrected early, before someone gets sick.

As per Standard 3.2.1 of the Food Standards Code (‘the Code’), Food Safety Programs in Australia must be based on HACCP concepts, more commonly known as HACCP principles.

‘HACCP’ stands for Hazard Analysis Critical Control Points, and is a system that was designed in the 1960s by NASA to ensure safe food for their astronauts. HACCP is used worldwide as a means of controlling food safety across many types of food businesses.

Food Safety Programs begin at the receiving stage as food enters the premises and follow it all the way to the point where it is served or purchased.

This guide was designed to provide practical advice for developing and implementing a Food Safety Program using the seven principles of HACCP:

- Conduct a Hazard Analysis

- Identify Critical Control Points

- Establish Critical Limits

- Monitor Critical Control Points

- Establish Corrective Actions

- Record Keeping

- Verification

The contents of your Food Safety Program should be communicated to all food workers in your business to ensure that everyone understands the proper procedures to follow when working, their responsibilities in terms of health and hygiene and any checks they need to perform as part of their role.

HACCP FOOD SAFETY PLAN KIT

For many food businesses, creating a Food Safety Program can seem overwhelming. The Australian Institute of Food Safety has created the AIFS HACCP Food Safety Plan Kit to help food businesses build and implement a compliant Food Safety Program.

The AIFS HACCP Food Safety Plan Kit covers all the steps and principles of the HACCP food safety system along with step-by-step instructions for completing a Food Safety Program. The kit includes HACCP plan templates, a stepby-step instructional guide and video training lessons. Food businesses also receive posters and signage for their establishment and a certificate of completion.

Conducting a Hazard Analysis

The first step is to identify all possible food safety hazards that could occur in your business. First, identify the processes used in your business.

These might include:

- receiving goods

- cooking food

- serving food

- waste disposal

Next, consider the food safety hazards (which can be anything that causes food to become harmful or unsafe) that could occur during these processes. Identify potential hazards and categorise them as biological, physical or chemical.

BIOLOGICAL CONTAMINATION

Biological contamination refers to food that is contaminated by substances produced by living creatures (e.g. humans, pests, microorganisms). This includes bacterial, viral and parasitic contamination that is transferred through saliva, pest droppings, blood or faecal matter.

PHYSICAL CONTAMINATION

Physical contamination refers to food that has been contaminated by a foreign object at some stage of the food production process. These objects have the ability to injure someone and can also potentially carry harmful biological or chemical contaminants.

CHEMICAL CONTAMINATION

Chemical contamination refers to food that has been contaminated by a chemical substance. Because chemicals are often used when cleaning in the kitchen, they can easily contaminate food.

Trace amounts may not lead to illness, but Food Handlers should take all reasonable precautions to prevent contamination from happening. In many cases, the identified hazard may fall into multiple categories.

As an example, some potential hazards that could occur during the receiving goods stage are:

- pests (biological, physical)

- improper delivery temperature (biological)

- expired products (biological)

- damaged packaging (biological, physical)

Complete this process for each identified hazard in your food business or related organisation.

Identifying Critical Control Points

Once you have identified all your food safety hazards, you need to identify critical control points (CCPs). A CCP is a step in the process where hazards can be reduced, eliminated or prevented. It is the point at which something is measured or checked.

Identifying CCPs will help to reduce the risk of food-borne illness by preventing the growth of dangerous bacteria and other microorganisms, as well as help to prevent cross-contamination between foods, which can trigger serious allergic reactions for some customers.

Some examples of CCPs are:

- the sign-off step when receiving deliveries

- checking the temperature of food before serving

- cooking food to a specific temperature

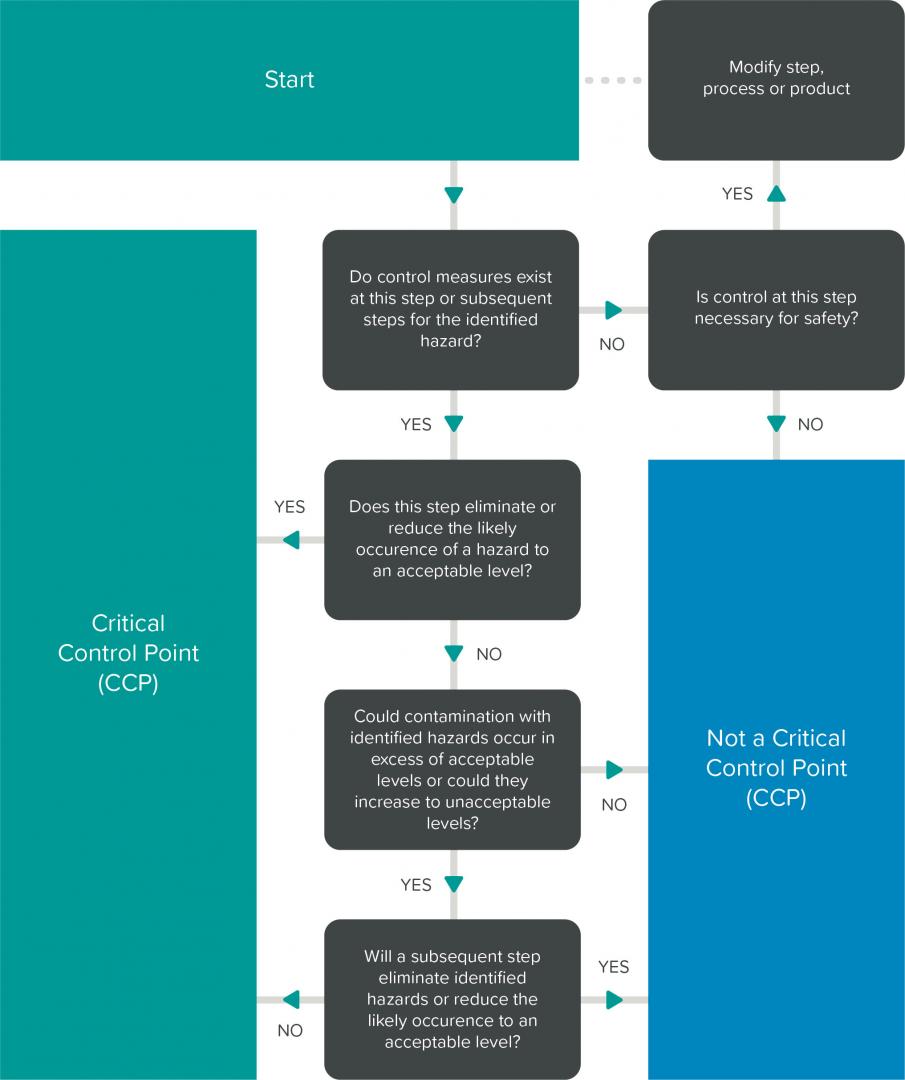

HOW TO IDENTIFY CCPs

One strategy that can be used to help identify CCPs in your food business is a decision tree. This can be helpful but is not a mandatory requirement of your Food Safety Program.

It is important to remember that there is no generic template that can be used to determine the CCPs in your food business — no cookie-cutter solution.

Even facilities that process or prepare similar food items will not necessarily identify the same hazards or CCPs. It depends on a myriad of factors specific to each food business or processing facility, such as physical layout, equipment and/or ingredients used and food preparation processes.

Here is an example of a CCP decision tree:

Establishing Critical Limits

Critical limits are applied at each of the critical control points (CCPs). A critical limit is a maximum or minimum value to which a food safety hazard (biological, chemical or physical) must be controlled at a CCP to prevent, eliminate or reduce the hazard to an acceptable level.

Each CCP must have one or more critical limits for each hazard.

Once you know where in your process you require critical limits, you need to determine or assign actual values for them.

This can be challenging, as there is a wide variety of hazards and each have different acceptable values. Sometimes, the appropriate critical limits are not readily available, making it necessary to conduct tests or obtain information from outside sources, such as regulatory guidelines or expert opinions.

If the information needed to set the critical limit is not available, make a judgement call; set a conservative value, erring on the side of caution. The reference materials and reasons used to set the critical limit should be kept as part of your Food Safety Program in order to justify your decisions.

Critical limits are generally concerned with parameters that are measurable with equipment or can be answered with a yes or no answer, such as:

- time

- temperature

- moisture level

- pH (acidity)

- best before or expiry dates

Monitoring Critical Control Points

Monitoring is essential to ensure that each process is within the critical limit determined for each critical control point (CCP). Monitoring involves performing an action to check that food is safe.

Monitoring techniques can be broken down into four different categories:

- Observation monitoring, which may include scheduled inspections, checking cleaning schedules and monitoring delivery checklists.

- Sensory monitoring, which involves using the senses (taste, smell, touch, sight) to check whether food is within critical limits. This may include checking food for unpleasant odours, feeling its texture or examining it for signs of contamination.

- Chemical monitoring, which may include checking the level of acidity of food, or conducting a nutritional, metal or residue analysis of food products.

- Physical monitoring, which involves checking elements such as temperature, time, pressure and/or weight of food items.

The best way to ensure that monitoring is being performed is by using checklists and other forms of documentation to record the results. Checklists allow you to review what corrective actions have taken place and identify where improvements to your Food Safety Program can be made.

Establishing Corrective Actions

Corrective actions are the actions that must be taken if a deviation from an acceptable critical limit occurs. Corrective actions are either immediate or preventative.

An immediate corrective action is stopping a breach that is happening now. For example:

- disposing of contaminated food

- rejecting a food delivery with signs of pest infestation

- refrigerating food to keep it out of the Temperature Danger Zone (5°C – 60°C)

A preventative corrective action is stopping a breach from occurring in the future. For example:

- performing routine maintenance on equipment

- changing work procedures

- training staff to follow food safety best practices

It is important to record and communicate any corrective actions that have been taken to the appropriate people within your business or organisation. If corrective action is necessary, you should:

- inform managers or supervisors of the breach

- record your assessment, including details of the CCP and critical limits that have been exceeded

- decide on and execute the appropriate corrective action

- record and communicate details about the corrective action and why it was done

Record Keeping

Record keeping is essential for the effective operation of your Food Safety Program, and must include an up-to-date hazard analysis and details of any corrective actions that have been taken in your food business.

There are many daily records associated with your Food Safety Program that must be kept up-to-date and stored safely. These may include:

- delivery checklists

- signed-off cleaning schedules

- temperature recordings

- pest inspection results

- staff training records

All employees should know:

- where the Food Safety Program is located

- what each employee is responsible for completing (e.g. cleaning schedules, temperature logs)

- when they need to perform checks

- who to report issues to

During an inspection, an Environmental Health Officer (EHO) may ask to review records and documentation such as those listed above.

You are required by law to provide this information to an EHO upon request. Food safety is essential to the success of any food business. Protect your customers, yourself and the long-term health of the business with a robust Food Safety Program.

Establishing Verification Procedures

It is important to perform an audit of your Food Safety Program at least once a year to check that it is working as expected.

Methods that are commonly used by food businesses include:

- internal inspections

- external audits

- employee feedback

Your Food Safety Program should be considered a ‘living document’. Expect to find opportunities for improvement and adjust your program accordingly.

Ask yourself the following questions:

- Are there any new foods or recipes being served?

- Have recipes changed for any existing dishes or food products?

- Have any preparation steps been changed?

- Are there any changes to food safety laws or regulations that will impact your operations?

- Are there any patterns that point to a need for additional Food Handler training?

If the answer is yes to any of these questions, you need to update your Food Safety Program.

Putting Your Food Safety Program into Action

An Environmental Health Officer (EHO) will be the best judge of the effectiveness of your Food Safety Program.

Your business will be visited by an EHO — commonly referred to as a Health Inspector or ‘Inspector’ — up to three times per year (or more, if they receive a complaint about your business).

When an EHO audits your food business, they will review your Food Safety Program and its records.

The records your business keeps are evidence that all food preparation steps and activities have been identified and documented. This is to ensure that every aspect of your food business has been optimised for food safety.

By creating a detailed (yet easy-to-understand) Food Safety Program based on the seven HACCP principles listed in this guide, you will drastically reduce the risk of food poisoning or allergy incidents in your business.

The AIFS HACCP Food Safety Plan Kit provides a deeper understanding of what a Food Safety Program requires, and can help you and your employees to create, implement and follow a Food Safety Program in your business.

Training on Food Safety Programs is also provided in the AIFS Food Handler course, AIFS Food Safety Supervisor course and the AIFS Food Safety Manager course.

About the Australian Institute of Food Safety

As Australia’s largest provider of food safety education, the Australian Institute of Food Safety is dedicated to helping organisations protect their business and their customers from food-borne illness.

As a community focused organisation we deliver public health information to food businesses and consumers in order to improve food safety throughout Australia.

AIFS delivers nationally recognised training that meets all federal and state compliance requirements related to food safety. This includes Food Safety Supervisor and Food Handler compliance training.

The mission of the Australian Institute of Food Safety is to reduce food-borne illness within Australia by educating, advocating and promoting food safety.